Quality nye Agbemɔ si le Aŋɔ Ŋuti Nusrɔ̃ƒe, si ŋu nyonyomedzikpɔkpɔ ƒe ɖoɖo sesẽ aɖe si do ƒome kple wo nɔewo doa alɔe .:

Wotiaa nu xoxowo koŋ be woawɔ ɖe silicone/rubber molds ƒe nudidi tɔxɛwo dzi, si wɔnɛ be woɖea nusiwo mede ŋgɔ o ɖesiaɖe ɖa.

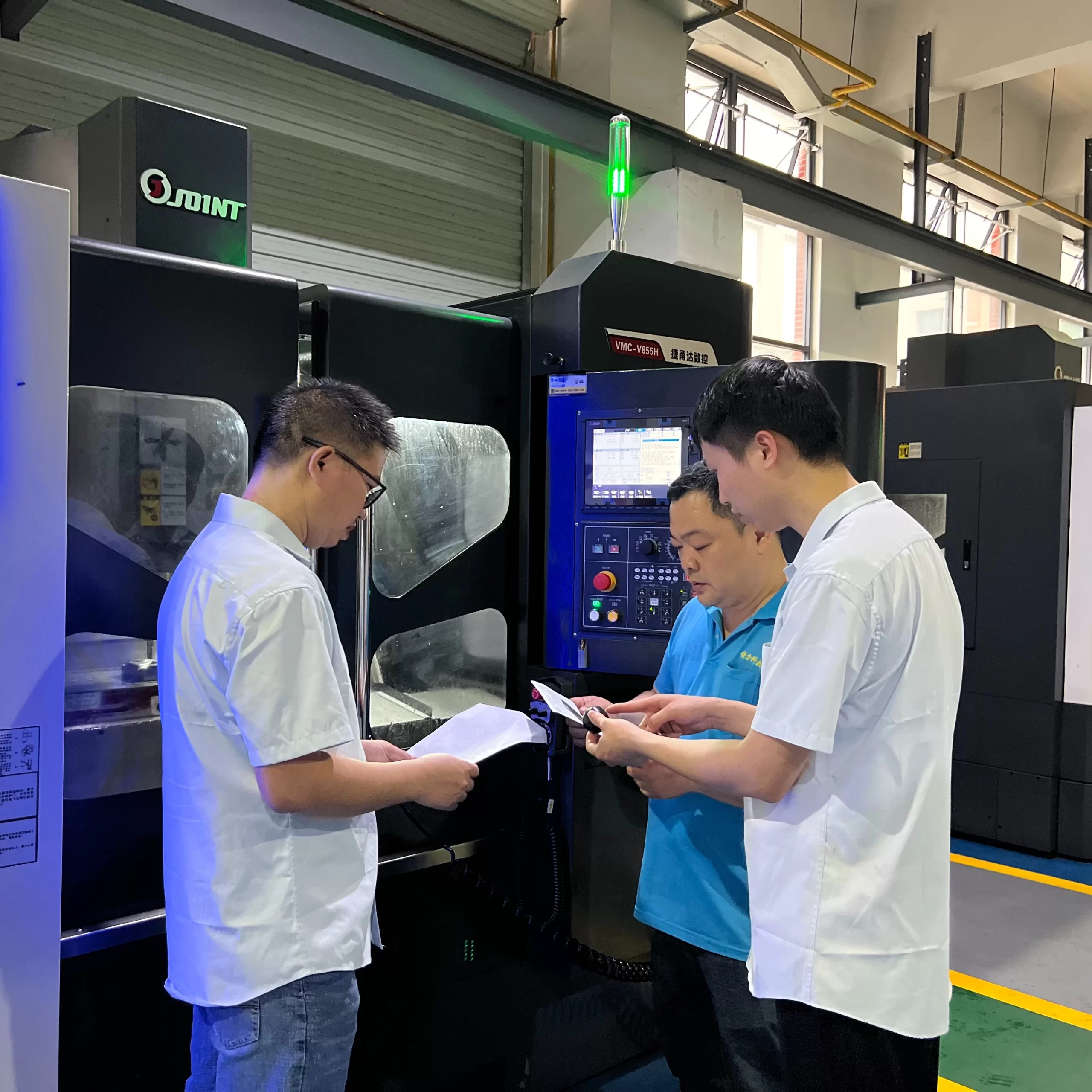

Mɔ̃ɖaŋudɔwɔwɔ ƒe ɖoɖo ɖesiaɖe nɔa te ɖe dɔwɔwɔ ƒe dzidzenu siwo me kɔ kple ŋkuléle ɖe wo ŋu ƒe ɖoɖowo dzi, si naa wokpɔa egbɔ be wokpɔa nyonyome dzi le afɔɖeɖe ɖesiaɖe me.

Select Language

Select Language